There are many processes that need inferential control because of the unfeasibility of primary variable measurement for one reason or the other.

An appropriate secondary or auxiliary measurements are carried out to accomplish the control. In this article, a few applications and an example of inferential control are presented.

Applications of Inferential Control

1. Distillation: In distillation, the controlled variables are the composition of the bottom and top products. Composition Analyzers like Gas Chromatographs are used to measure composition. It is both difficult and expensive to install and maintain these analyzers online. It also introduces significant time delays (3 to 15 minutes). In these cases, the temperature of the intermediate trays is measured to infer composition. Corrections can be made to the temperature setpoint based on the results of composition measurement.

2. Polymerization Reactor: In polymerization reactors, the primary controlled variables are molecular weight distribution and viscosity of the product. It is difficult to measure these variables. Control is accomplished using secondary measurements like feed flow, temperature, and pressure of the reactor.

3. Drying: In solids drying operations, the primary variable is the moisture content of the dried product. The use of online sensors to detect moisture content is difficult. The inlet temperature, the temperature of the solids, the humidity of the drier exhaust air are measured to take a control action.

4. Paper-Making: In paper-making, the moisture content and the brightness of the product are variables to be controlled. These primary variables cannot be measured directly. Secondary measurements like temperature and reflectance are carried out to accomplish control action.

5. Naphtha Cracking: Naphtha is a petroleum product produced by the distillation of crude oil. It is cracked to form high octane products. This reaction is carried out in large catalytic reactors. The octane number of the product is to be controlled. The temperature and pressure of the reactor are measured to infer the unmeasurable octane number.

Example of Inferential Control

Overhead composition control in a Distillation Column

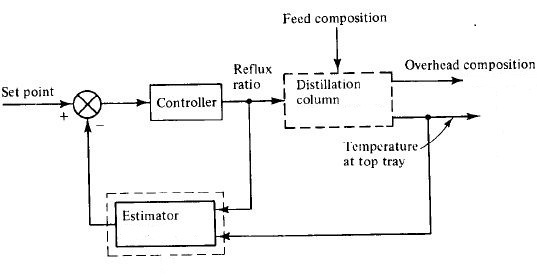

Consider a distillation column with 16 trays which separates a mixture of propane-butane into two products. The control objective is to maintain overhead product molar composition 95% in propane. The composition of the overhead product cannot be measured directly. So, the inferential control scheme is employed and the overhead composition is estimated from the measurement of temperature at the top tray.

Controlled Variable (Primary Process Variable): Overhead Composition

Inferential Variable (Secondary variable): Temperature at top tray

Manipulated Variable: Reflux Ratio

Disturbance Variable: Feed Composition

The adaptive control can be employed along with the inferential control in the overhead composition control in a distillation column. The intermittent measurement of the overhead composition is made and it is compared against its desired setpoint. The error can be used to correct the estimator through an adaptive mechanism. The adaptive mechanism can be used to check the effective control by the inferential control scheme.

Previous Reading: Inferential Control - An Introduction

Consider a distillation column with 16 trays which separates a mixture of propane-butane into two products. The control objective is to maintain overhead product molar composition 95% in propane. The composition of the overhead product cannot be measured directly. So, the inferential control scheme is employed and the overhead composition is estimated from the measurement of temperature at the top tray.

Controlled Variable (Primary Process Variable): Overhead Composition

Inferential Variable (Secondary variable): Temperature at top tray

Manipulated Variable: Reflux Ratio

Disturbance Variable: Feed Composition

|

| Overhead composition control in a Distillation Column |

Previous Reading: Inferential Control - An Introduction

This again was a helpful read for someone with Instrumentation background like me. Keep up the good work!

ReplyDelete